Resin 3D Printing

Resin Additive Manufacturing

Resin 3D printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finishes. Resin 3D printers all utilise some form of light source, such as a laser or projector, to harden liquid resin into plastic. The main divergence with other forms of plastic 3D Printing is in the arrangement of the key machine parts, such as the build platform, the light source, and the resin tank.

Resin parts tend to have greater accuracy, the best resolution, sharper details and the smoothest surface finishes of all 3D printing technologies. The main benefit however, lies in the great versatility of materials. manufacturers have created. Resin formulations with a wide range of optical, mechanical, and thermal properties match those of standard, engineering, and industrial thermoplastics and allow for a wide range of applications.

At Complete 3D we offer three types of resin 3D Printing: SLA, LCD/DLP, and MJP.

Our 3D Systems Resin 3D Printers

LCD and DLP additive manufacturing is very similar in a variety of ways. LCD 3D Printers use a LCD display module to project a certain light pattern which is then used to cure resin in the resin vat. LED light is used as the light source while the LCD screen controls the light pattern. Light is emitted from the LED lamp. It then passes through an LCD screen and is absorbed by the resin. An image of each layer is generated on the LCD screen while an entire layer is hardened at once. DLP 3D printers are very similar but are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer. The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

Entry Level LCD/DLP Resin Printers

Peopoly Phenom

Popular Large MSLA (LCD+LED) Printer

An entry-level industrial MSLA printer. The phenom has a unique mix of size, speed and cost. Attractive for businesses that want faster and higher resolution 3D printing without the high price.

Best used for: Prototyping

Max build volume: 277 x 156 x 400mm

Resolution: 72 Microns

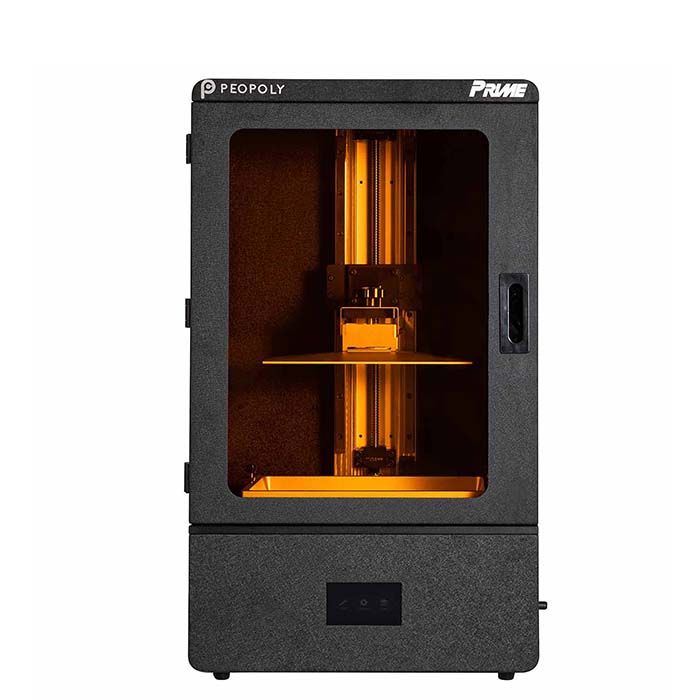

Peopoly Phenom Prime

Fast and Sharp MSLA (LCD+LED) Printer

Building upon the successful features of the Phenom, the next evolution of MSLA printers centres around the panels. The phenom prime goes beyond 4K to monochrome and improves resolution and print quality.

Best used for: Prototyping

Max build volume: 277 x 156 x 400mm

Resolution: 51 Microns

Peopoly Phenom L

Large Format Resin MSLA (LCD+LED) Printer

After their successful launch of the Phenom Peopoly have introduced the Phenom L, the largest MLSA printer on the market and the perfect next step for industrial users looking for a larger build volume.

Best used for: Prototyping

Max build volume: 345 x 194 x 400mm

Resolution: 90 Microns

Industrial LCD/DLP 3D Printers

3D Systems Figure 4

Fast & Affordable Resin Printer

The Figure 4 offers speed, quality, and accuracy with industrial grade durability, all at an affordable price. Giving prototyping and production application diversity to its user.

Best used for: Rapid Tooling, functional prototyping, Jigs and fixtures, End-use durable plastic parts

Max build volume: 125 x 70 x 195 mm

Resolution: 60 Microns

Photocentric LC Opus

Quick Open Source Resin Printer

The Photocentric Liquid Crystal Opus delivers fast, highly accurate prints, suitable for a wide variety of applications including dental and orthodontic industries.

Best used for: Prototyping, low volume production, dental models and clear dental aligners

Max build volume: 310 x 174 x 200 mm

Resolution: 81 Microns

Photocentric LC Magna

Best For Custom Manufacturing

With the combination of a large build volume, exceptional reliability, and fast print speeds, the LC Magna offers the perfect solution for custom resin manufacturing.

Best used for: Prototyping, low to medium volume production, jigs and fixtures and end-use parts

Max build volume: 510 x 280 x 350 mm

Resolution: 137 Microns

Our 3D Systems SLA 3D Printers

SLA is all about precision and accuracy, so it is often used when form, fit, and assembly are critical. The tolerances on SLA parts are typically less than 0.05 mm, and SLA offers the smoothest surface finish of any additive manufacturing process. With the quality SLA can achieve, it is particularly useful for creating highly precise casting patterns (e.g. for injection moulding, casting, and vacuum casting) as well as functional prototypes, presentation models, and form and fit testing. SLA technology is extremely versatile and can be used in any number of areas where precision is paramount.

ProJet 6000 HD

Professional Grade SLA Printer

3D Print SLA parts with unrivalled accuracy and surface finish in a range of materials that match/exceed traditional plastic properties. Easily swap material modules for flexible use.

Best used for: Master patterns for vacuum casting, sacrificial patterns for metal casting

tools, moulds and dies

Max build volume: 250 x 250 x 250 mm

Resolution: 4000 x 4000 DPI

ProJet 7000 HD

Large Format & Multi-Material

The ProJet 7000 HD 3D printer builds on the advantages of SLA allowing for single large-sized or series of smaller printed prototypes, patterns and end-use parts to be printed.

Best used for: Master patterns for vacuum casting, sacrificial patterns for metal casting

Tools, moulds and dies

Max build volume: 380 x 380 x 250 mm

Resolution: 4000 x 4000 DPI

PRO X 800

Large Industrial SLA 3D Printer

Highly efficient large-scale 3D printer, with minimal waste. Productive and reliable, with the highest accuracy, and the broadest range of additive manufacturing materials.

Best used for: Master patterns for vacuum casting, sacrificial patterns for metal casting

Tools, moulds and dies

Max build volume: 650 x 750 x 550 mm

Resolution: 4000 x 4000 DPI

Our 3D Systems MJP 3D Printers

MultiJet Printing (MJP) technology produces high fidelity, true-to-CAD parts, with fast print times, easy operation and simple post-processing for high productivity and true simplicity, from file to finished part. The wide range of VisiJet materials for the ProJet MJP Series enables a broad set of applications for concept modelling, form and fit testing, functional prototyping, fluid flow analysis, rapid tooling, jigs and fixtures, casting patterns and medical applications.

ProJet MJP 2500 Plus

Best For Functional Prototypes

The 3D Systems Projet MJP 2500 Plus allows its operator to rapidly create high fidelity, functional prototypes. The 2500 Plus is an industrial grade multijet 3D printer with relentless speed and high quality.

Best used for: Concept modelling, validation prototyping, biocompatible medical devices, jigs, fixtures and tools

Max build volume: 294 x 211 x 144 mm

Resolution: 800 x 900 x 790 DPI

ProJet MJP 2500W

Large Multi-Material Printer

The ProJet MJP 2500W is a 100% wax jewellery patterns 3D printer that adjusts to your workflow, delivering from several short-run batches a day to the next day for larger builds at high productivity.

Best used for: Pre-series and series production of jewellery metal pieces, customised jewellery metal pieces

Max build volume: 294 x 211 x 144 mm

Resolution: 1200 x 1200 x 1600 DPI

ProJet 2500 IC

Wax Casting Pattern Production

Ideal for customised components, bridge manufacturing, and low volume production. This printer produces wax casting patterns at a fraction of the cost and time of standard wax pattern production.

Best used for: Low to mid-volume production, Bridge manufacturing, instant design validation, Customised metal parts

Max build volume: 294 x 211 x 144 mm

Resolution: 600 x 600 x 600 DPI

ProJet 3600

High Capacity and Performance

ProJet MJP 3600 delivers true-to-CAD quality and accuracy, superior edge fidelity and surface finish. Built for ease, this series of printers stands out among the rest.

Best used for: Validation prototyping, rapid tooling, extremely fine detail casting patterns, jigs and fixtures

Max build volume: 298 x 185 x 203 mm

Resolution: 750 x 750 x 1600 DPI

ProJet 3600W

Affordable Jewellery Wax Printer

The 3600W generates 100% RealWax micro-detail, high fidelity precision metal casting patterns for high capacity production. For reliable and repeatable casting efficiency.

Best used for: Pre-series and series production of jewellery metal pieces & customised jewellery metal pieces

Max build volume: 298 x 185 x 203 mm

Resolution: 800 x 900 x 790 DPI

ProJet 5600

Large Format Resin Printer

Delivering a diverse array of mechanical performances, the ProJet MJP 5600 is a multi-material composite printer that generates stunningly realistic, functional prototypes & patterns for many applications.

Best used for: Prototyping, low to medium volume production, jigs and fixtures, end-use parts

Max build volume: 518 x 381 x 300 mm

Resolution: 800 x 900 x 790 DPI